You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

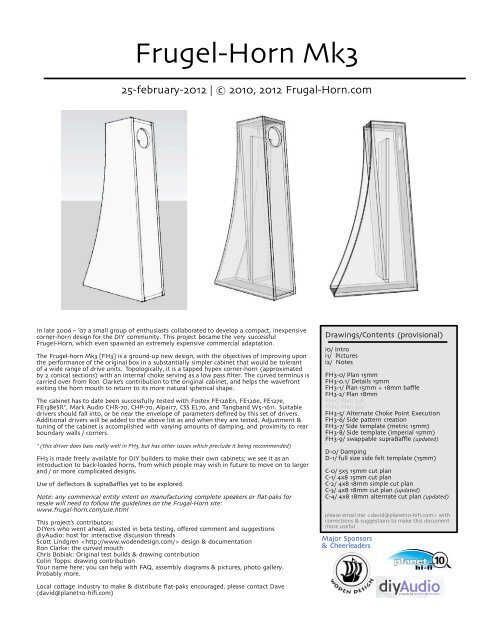

In late 2006 – ’07 a small group of enthusiasts collaborated to develop a compact, inexpensive<br />

corner-horn design for the DIY community. This project became the very successful<br />

<strong>Frugel</strong>-<strong>Horn</strong>, which even spawned an extremely expensive commercial adaptation.<br />

The <strong>Frugel</strong>-horn <strong>Mk3</strong> [FH3] is a ground-up new design, with the objectives of improving upon<br />

the performance of the original box in a substantially simpler cabinet that would be tolerant<br />

of a wide range of drive units. Topologically, it is a tapped hypex corner-horn (approximated<br />

by 2 conical sections) with an internal choke serving as a low pass filter. The curved terminus is<br />

carried over from Ron Clarke’s contribution to the original cabinet, and helps the wavefront<br />

exiting the horn mouth to return to its more natural spherical shape.<br />

The cabinet has to date been successfully tested with Fostex FE126En, FE126e, FE127e,<br />

FE138eSR*, Mark Audio CHR-70, CHP-70, Alpair7, CSS EL70, and Tangband W5-1611. Suitable<br />

drivers should fall into, or be near the envelope of parameters defined by this set of drivers.<br />

Additional drivers will be added to the above list as and when they are tested. Adjustment &<br />

tuning of the cabinet is accomplished with varying amounts of damping, and proximity to rear<br />

boundary walls / corners.<br />

* (this driver does bass really well in FH3, but has other issues which preclude it being recommended)<br />

FH3 is made freely available for DIY builders to make their own cabinets; we see it as an<br />

introduction to back-loaded horns, from which people may wish in future to move on to larger<br />

and / or more complicated designs.<br />

Use of deflectors & supraBaffles yet to be explored.<br />

<strong>Frugel</strong>-<strong>Horn</strong> <strong>Mk3</strong><br />

25-february-2012 | © 2010, 2012 Frugal-<strong>Horn</strong>.com<br />

Note: any commerical entity intent on manufacturing complete speakers or flat-paks for<br />

resale will need to follow the guidelines on the Frugal-<strong>Horn</strong> site:<br />

www.frugal-horn.com/use.html<br />

This project’s contributors:<br />

DIYers who went ahead, assisted in beta testing, offered comment and suggestions<br />

diyAudio: host for interactive discussion threads<br />

Scott Lindgren design & documentation<br />

Ron Clarke: the curved mouth<br />

Chris Bobiak: Original test builds & drawing contribution<br />

Colin Topps: drawing contribution<br />

Your name here: you can help with FAQ, assembly diagrams & pictures, photo gallery.<br />

Probably more.<br />

Local cottage industry to make & distribute flat-paks encouraged, please contact Dave<br />

(david@planet10-hifi.com)<br />

Drawings/Contents (provisional)<br />

i0/ Intro<br />

i1/ Pictures<br />

i2/ Notes<br />

FH3-0/ Plan 15mm<br />

FH3-0.1/ Details 15mm<br />

FH3-1/ Plan 15mm + 18mm baffle<br />

FH3-2/ Plan 18mm<br />

FHx/ Plan 5/8”<br />

FHx/ Plan 3/4”<br />

FH3-5/ Alternate Choke Point Execution<br />

FH3-6/ Side pattern creation<br />

FH3-7/ Side template (metric 15mm)<br />

FH3-8/ Side template (imperial 15mm)<br />

FH3-9/ swappable supraBaffle (updated)<br />

D-0/ Damping<br />

D-1/ full size side felt template (15mm)<br />

C-0/ 5x5 15mm cut plan<br />

C-1/ 4x8 15mm cut plan<br />

C-2/ 4x8 18mm simple cut plan<br />

C-3/ 4x8 18mm cut plan (updated)<br />

C-4/ 4x8 18mm alternate cut plan (updated)<br />

please email me with<br />

corrections & suggestions to make this document<br />

more useful<br />

Major Sponsors<br />

& Cheerleaders

Pictures<br />

25-february-2012<br />

more pictures at http://www.diyaudio.com/forums/full-range/199849-fh3-build-gallery.html

Notes<br />

———————————————————————————————<br />

'/ quality multi#ply/plywood is recommended& In general" void free"<br />

the greater number of plies the better<br />

,/ reference build is ,6mm plywood" to allow rebate for some drivers<br />

,%mm ba7es recommended 0ie Alpair 81<br />

+/ if MDF or particle board used a minimum panelthickness of ,%mm"<br />

good multi#ply minimum ,+mm<br />

)/ the most di9cult detail in the build is the joint at the bottom of<br />

back" inside divider& A number of means to achieve this are detailed<br />

$/ a removable vestigial supraBa7e is shown that allows<br />

experimentation with di-erent drivers<br />

6/ a full size supraBa7e can be added as shown in the <strong>Frugel</strong>#<strong>Horn</strong><br />

Mk, document<br />

*/ A full height rear de.ector based on that shown in the <strong>Frugel</strong>#<strong>Horn</strong><br />

Mk, document can be added<br />

8/ a stealthWoofer based on a full#height de.ector is under<br />

development&<br />

Donations<br />

————————————————————————————<br />

<strong>Frugel</strong>#<strong>Horn</strong>s have always been free for DIY builders to<br />

construct& We received many inquiries by buiders who wanted<br />

to send some money& For this iteration we would encourage you<br />

to pay it forward with a donatation of money or time to some<br />

charitable organization& Listed below are some choosen by the<br />

three main contributors to the design & documentation&<br />

Quite literally" every little helps&<br />

Royal British Legion: www&britishlegion&org&uk<br />

Alzheimer!s Research UK: www&alzheimersresearchuk&org<br />

Cancer Research UK: www&cancerresearchuk&org<br />

Donor!s Choose: www&donorschoose&org<br />

Save The Children: www&savethechildren&org<br />

Big Brothers Big Sisters: www&bbbs&org<br />

Chris ,<br />

Chris +<br />

Chris )<br />

———————————————————————————————<br />

for those without major woodworking kit" a growing number of<br />

independent .at#pak vendors ar ecoming on#line& Canada 0North<br />

America1" Netherlands & UK 0Europe1 & Australia as of this document<br />

revision<br />

Notes<br />

)'#september#+',,<br />

Comments & tips pulled form forum posts<br />

———————————————————————————————<br />

Bob Brines:<br />

Taking Colin!s diagram !sheet C"#$" here is how I would one#man it<br />

out of a $x% panel&<br />

'& Build yourself a T#square cutting guide out of scrap material& You<br />

can (nd the instructions out there on the Internet&<br />

''& I have a )!x*! sacri(cial table top on a pair of saw horses& I can still<br />

manage to get a $x% sheet of plywood on it" but I can no longer get a<br />

sheet of MDF on it& For MDF" I just drop the sheet on the driveway<br />

and put $ +x$!s under it&<br />

,& With a circular saw" cut o- the $ ,$'mm pieces&<br />

+& Cut between the remaining doubled pieces&<br />

)& Now you can rip the individual pieces on a table saw as long as you<br />

can rig some kind of out.ow table& I have a jig that (ts my router<br />

table so that it can double as an out.ow table for the table saw& Of<br />

course" if you don!t have a table saw" you can do this with a circular<br />

saw and the rip fence you made above&<br />

You can get the two cross cuts done at Lowes!/HD 0speaking to the<br />

USA now1" but my experience is that their panel saws are not square<br />

in any axis and I have to re#cut the ends& Also" the utility blade in their<br />

saw really tears up the cut& I have a *' tooth blade in my circular saw<br />

that does an acceptable job& Not as good as the %' tooth blade in my<br />

table saw" but acceptable&<br />

That!s my technique& YMMV&<br />

Bob<br />

———————————————————————————————<br />

PDRCanada:<br />

Another tip for cutting sheet goods on saw horses&&&&&&<br />

Go to your nearest hardware store buy a +!x$! pc of + or )2 white<br />

styrofoam and a roll of duct tape&<br />

Cut the stryo to match the top of your saw horses&&&&&&use the duct<br />

tape to fasten it around the top of the horse&<br />

You can now cut your sheets with out hanging them over the saw<br />

horses& Just cut thru the styro&&&&&make sure your styro is deeper than<br />

your saw cut&<br />

When the styro gets beat up&&&remove and replace&<br />

This method is used on jobsites all over to cut large panels&<br />

———————————————————————————————<br />

Poultrygeist:<br />

A3er much frustration in searching for ,/+ 4 0 ,+mm 1 cotton or wool<br />

felt I found an unlimited supply at my local auto junk yard& The carpet<br />

backing from ,55'!s Fords is ,/+ inch thick" works great and costs<br />

nothing& Had it not been up for sale I would have scavenged my own<br />

Mustang but instead I found a F,6' donor which surrendered enough<br />

felt for a herd of horns&

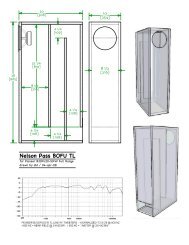

'<br />

6$ &"07<br />

!/#& mm<br />

radius 1-234<br />

/'<br />

6$ &"07<br />

0*2°<br />

&5<br />

6! !"$7<br />

002<br />

6!/ !!"!-7<br />

Notes:<br />

!" drawn with !#mm material<br />

$" optional %&'' mm wide"diameter supra(ba)e not<br />

shown* Its purpose is to move the ba)e(step drop o+ to<br />

where the horn action starts ,attening lower midrange FR<br />

&" intended for Fostex FE!$-En. CHR(/'. Alpair /. EL/'<br />

0" damping will di+er for each driver<br />

!/!<br />

6- &"07<br />

!##<br />

6- &"&$7<br />

0&$<br />

6!/7<br />

5#*$°<br />

!0'<br />

6# !"$7<br />

/'<br />

6$ &"07<br />

/-<br />

6$ &!"&$7<br />

0*5°<br />

520<br />

6&# &"!-7<br />

5-0<br />

6&07<br />

<strong>Frugel</strong>(<strong>Horn</strong> Mk& !v'<br />

sheet FH&(' 8 !#mm Plan<br />

designed by S Lindgren 9 drawn by dld<br />

$/(september($'!!<br />

© $'!'. $'!! Frugal(<strong>Horn</strong>*com<br />

!/'<br />

6- !!"!-7<br />

!0'<br />

6# !"$7

#/1°<br />

Notes:<br />

!,!<br />

)* '"-+<br />

<strong>Frugel</strong>.<strong>Horn</strong> Mk' !v(<br />

sheet FH'.(/! % details !#mm<br />

designed by S Lindgren 0 drawn by dld<br />

$1.september.$(!!<br />

© $(!(2 $(!! Frugal.<strong>Horn</strong>/com<br />

-'-<br />

)!, '"'$+<br />

-/&°<br />

!" drawn with !#mm material<br />

$" joint detail at lower end of the internal panels % # degree<br />

angle cut on the inside of rear panel can be cut on table saw<br />

with tenoning jig and blade set to #deg or carefully sanded<br />

!#mm radius<br />

-/&°<br />

&'(<br />

)'$ !!"!*+<br />

-/1°<br />

this end can be<br />

rounded<br />

,#*<br />

)$1 '"-+

'<br />

6$ &"07<br />

!/#& mm<br />

radius 1-234<br />

/'<br />

6$ &"07<br />

0*2°<br />

&5<br />

6! !"$7<br />

!#mm radius<br />

0#$<br />

6!/ !&"!-7<br />

Notes:<br />

!" drawn with !#mm material<br />

$" optional %&'' mm wide"diameter supra(ba)e not<br />

shown* Its purpose is to move the ba)e(step drop o+ to<br />

where the horn action starts ,attening lower midrange FR<br />

&" intended for Fostex FE!$-En. CHR(/'. Alpair /. EL/'<br />

0" damping will di+er for each driver<br />

!/!<br />

6- &"07<br />

!##<br />

6- &"&$7<br />

0&$<br />

6!/7<br />

5#*$°<br />

!0'<br />

6# !"$7<br />

/'<br />

6$ &"07<br />

/-<br />

6$ &!"&$7<br />

0*5°<br />

520<br />

6&# &"!-7<br />

5-0<br />

6&07<br />

<strong>Frugel</strong>(<strong>Horn</strong> Mk& !v'<br />

sheet FH&(! 8 !#mm Plan w !5mm<br />

ba)e<br />

designed by S Lindgren 9 drawn by dld<br />

$/(september($'!!<br />

© $'!'. $'!! Frugal(<strong>Horn</strong>*com<br />

!/'<br />

6- !!"!-7<br />

!0'<br />

6# !"$7

'<br />

6$ &"07<br />

!/#& mm<br />

radius 1-234<br />

/'<br />

6$ &"07<br />

0*2°<br />

!5mm radius<br />

&5<br />

6! !"$7<br />

0#2<br />

6!5 !"!-7<br />

Notes:<br />

!" drawn with !#mm material<br />

$" optional %&'' mm wide"diameter supra(ba)e not<br />

shown* Its purpose is to move the ba)e(step drop o+ to<br />

where the horn action starts ,attening lower midrange FR<br />

&" intended for Fostex FE!$-En. CHR(/'. Alpair /. EL/'<br />

0" damping will di+er for each driver<br />

!20<br />

6/ #"57<br />

!#5<br />

6- /"&$7<br />

0&2<br />

6!/ 2"&$7<br />

5#*$°<br />

!0'<br />

6# !"$7<br />

/'<br />

6$ &"07<br />

/-<br />

6&7<br />

0*5°<br />

2''<br />

6&# /"!-7<br />

5-0<br />

6&07<br />

<strong>Frugel</strong>(<strong>Horn</strong> Mk& !v'<br />

sheet FH&($ 8 !5mm Plan<br />

designed by S Lindgren 9 drawn by dld<br />

$/(september($'!!<br />

© $'!'. $'!! Frugal(<strong>Horn</strong>*com<br />

!/-<br />

6- !#"!-7<br />

!0'<br />

6# !"$7

!"#<br />

$% &%'(&)<br />

Note: example uses !%mm material<br />

As originally designed<br />

A di*cult piece to cut<br />

Modi+ed for easier build<br />

Adds an additional piece, not all that tolerent<br />

of thicker material<br />

Alternateeasier build<br />

Overcomes material thickness issues-<br />

Requires extra material . !'& round with<br />

radius of build material<br />

<strong>Frugel</strong>/<strong>Horn</strong> Mk( !v0<br />

sheet FH(/% . alternate choke point<br />

execution<br />

designed by S Lindgren 1 drawn by dld<br />

&#/september/&0!!<br />

© &0!0, &0!! Frugal/<strong>Horn</strong>-com

!""<br />

#$% $&!'<br />

.."<br />

#)3 ))&)('<br />

A<br />

.."<br />

#)3 ))&)('<br />

C<br />

D<br />

B<br />

()<br />

#* )$&$*'<br />

<strong>Frugel</strong>2<strong>Horn</strong> Mk$ )v4<br />

sheet FH$2( 5 curve chord & height<br />

designed by S Lindgren 6 drawn by dld<br />

*32september2*4))<br />

© *4)4+ *4)) Frugal2<strong>Horn</strong>1com<br />

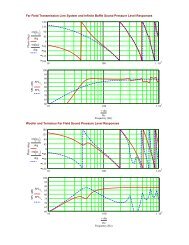

To fabricating a side panel template by<br />

hand+ the curve can easily be drawn<br />

using a narrow ,exible board -)&./ MDF<br />

works great0 and the . points as<br />

dimensioned1<br />

Mark points A+B -chord ends0+ C -chord<br />

centre line0 and D -segment height0<br />

on the work2piece1 Use a square to draw a<br />

perpendicular line -C2D0<br />

Clamp or screw a wood block straddling the<br />

centreline at D+ clamp the<br />

,exible board to this block and each end of<br />

the chord - A & B0 then draw<br />

the curve1<br />

Cut to the outside with jig or band saw+ and<br />

carefully sand to line

!<br />

"<br />

#<br />

$<br />

%<br />

&!<br />

&"<br />

&#<br />

&$<br />

&%<br />

"!<br />

""<br />

"#<br />

"$<br />

"%<br />

(!<br />

("<br />

(#<br />

($<br />

(%<br />

#!<br />

#"<br />

##<br />

#$<br />

#%<br />

)!<br />

)"<br />

)#<br />

)$<br />

)%<br />

$!<br />

$"<br />

$#<br />

$$<br />

$%<br />

*!<br />

*"<br />

*#<br />

*$<br />

*%<br />

%!<br />

%"<br />

%#<br />

%$<br />

%%<br />

+!<br />

'"! '&% '&$ '&#<br />

&%%<br />

,* &(-(".<br />

'&" '&! '%<br />

'$<br />

'#<br />

'"<br />

&%)<br />

,* +-(".<br />

*$<br />

," (&-(".<br />

! " # $ % &! &" &# &$ &% "! "" "# "$ "%<br />

<strong>Frugel</strong>'<strong>Horn</strong> Mk( &v!<br />

sheet FH('* / side pattern 0&cm grid1<br />

designed by S Lindgren 2 drawn by dld<br />

"*'september'"!&&<br />

© "!&!3 "!&& Frugal'<strong>Horn</strong>4com<br />

%+#<br />

,() (-&$.

-<br />

(<br />

+<br />

%<br />

#<br />

&<br />

)<br />

,<br />

!<br />

"<br />

(-<br />

((<br />

(+<br />

(%<br />

(#<br />

(&<br />

()<br />

(,<br />

(!<br />

("<br />

+-<br />

+(<br />

++<br />

+%<br />

+#<br />

+&<br />

+)<br />

+,<br />

+!<br />

+"<br />

%-<br />

%(<br />

%+<br />

%%<br />

%#<br />

%&<br />

.! ., .) .&<br />

(!!<br />

$, (%'%+*<br />

.# .% .+ .( -<br />

(!&<br />

$, "'%+*<br />

,)<br />

$+ %('%+*<br />

( + % # & ) , ! " (- ((<br />

<strong>Frugel</strong>.<strong>Horn</strong> Mk% (vsheet<br />

FH%.! / side pattern 0('+1 grid2<br />

designed by S Lindgren 3 drawn by dld<br />

+,.september.+-((<br />

© +-(-4 +-(( Frugal.<strong>Horn</strong>5com<br />

!"#<br />

$%& %'()*

<strong>Frugel</strong>-<strong>Horn</strong> <strong>Mk3</strong> 1v0<br />

sheet FH3-9 – removable supraBaffle<br />

(15mm)<br />

designed by C Bobiak | drawn by dld<br />

26-november-2011<br />

© 2010, 2011 Frugal-<strong>Horn</strong>.com<br />

Notes:<br />

0/ drawn with 18mm panels<br />

1/ shown on FH3 in 15mm material<br />

2/<br />

these dimensions allow for a small gap<br />

to accomodate veneer,laminate etc, if<br />

needed the wings can be made tight to<br />

the sides and the vertical edges can be<br />

sanded flush.<br />

85<br />

[3 11/32]<br />

86<br />

[3 3/8]<br />

cut out on backside of sB is<br />

20mm down from the top<br />

(15mm pnels, would be<br />

23mm down with 18mm<br />

panels)<br />

200<br />

[7 7/8]<br />

BaffleCutout<br />

175<br />

[6 7/8]<br />

115<br />

[4 17/32]<br />

208<br />

[8 3/16]<br />

120<br />

[4 23/32]<br />

70<br />

[2 3/4]<br />

165<br />

[6 1/2]<br />

110<br />

[4 11/32]

!"#$ %!#mm& cotton or wool felt<br />

!" FE!#3En blue 4 orange<br />

#" CHR5, blue 4 orange 4 #,.2,g<br />

+" EL5, blue 4 orange 4 #,.2,g<br />

2" A5 blue 4 orange 4 #,.2,g<br />

starting point 8 +,<br />

grams of poly(u) -<br />

average ,'9 lbs'01+<br />

%yellow 4 green&<br />

poly.(u) %BAF/ acoustistu)/ pillow stu6ng .. di)erent<br />

colours represent di)erent 7zones$ to add stu6ng too&<br />

increasing density as you approach<br />

the point' Take the equal density<br />

(u) on the right and squeeze it into<br />

the point %*+,g - ! oz &<br />

<strong>Frugel</strong>.<strong>Horn</strong> Mk+ !v,<br />

sheet D., 8 damping plan<br />

designed by S Lindgren : drawn by dld<br />

#5.september.#,!!<br />

© #,!,/ #,!! Frugal.<strong>Horn</strong>'com<br />

walls lined around driver to minimize<br />

re(ections<br />

this is the area subject<br />

to additional poly.(u)<br />

damping/ depends on<br />

driver<br />

see notes page ix for<br />

driver.by.driver<br />

%at !"# lb"01+ this<br />

volume would need<br />

*2,g %!'2 oz& of (u)

!*&<br />

+, !.%/&-<br />

Full Size when printed at !""#<br />

Remember these need to be mirror image pairs<br />

Note:<br />

speci$cally for !%&' felt material as relevant to planet!"(hi$ )atpak kits<br />

!,*<br />

+0 !%!0-<br />

<strong>Frugel</strong>(<strong>Horn</strong> Mk/ !v"<br />

sheet D(! 1 Side felt template 2!,mm3<br />

designed by S Lindgren 4 drawn by dld<br />

&5(september(&"!!<br />

© &"!"6 &"!! Frugal(<strong>Horn</strong>7com<br />

!*"<br />

+, !%&-

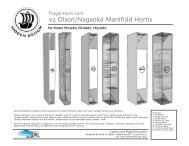

$/%<br />

-' $()0<br />

Notes:<br />

$( 'mm kerf & trim allowance<br />

)( very tight cut plan<br />

1$'<br />

-#) #(#)0<br />

*/$<br />

-)2 '(#)0<br />

internal<br />

internal<br />

back<br />

back<br />

bottom top<br />

ba!e<br />

<strong>Frugel</strong>"<strong>Horn</strong> Mk# $v%<br />

Sheet C"% & 'x' $'mm cut sheet<br />

layout by Chris Bobiak<br />

drawn by dld ( )*"sept")%$$<br />

© )%$%+ )%$$ Frugal"<strong>Horn</strong>,com<br />

top<br />

bottom<br />

ba!e<br />

$/%<br />

-' $()0<br />

$*)<br />

-. #(/0<br />

/#/<br />

-$* #(#)0<br />

121<br />

-#' #(10

'#)<br />

0"+ "*"+1<br />

,&#<br />

0+2 )*"+1<br />

back<br />

#&$<br />

0) #*+1<br />

#&$<br />

0) #*+1<br />

back<br />

internal<br />

internal<br />

top<br />

bottom<br />

ba/e<br />

top<br />

bottom<br />

ba/e<br />

#,+<br />

03 "*&1<br />

&"&<br />

0#, "*"+1<br />

'2'<br />

0") "*'1<br />

<strong>Frugel</strong>!<strong>Horn</strong> Mk" #v$<br />

Sheet C!# % &x'( #)mm cut sheet<br />

layout by David Dlugos<br />

drawn by dld * +,!sept!+$##<br />

© +$#$- +$## Frugal!<strong>Horn</strong>.com<br />

Notes:<br />

#* )mm kerf & trim allowance<br />

+* room to increase kerf for CNC<br />

"* works for #++$x+&&$mm sheets

!"#<br />

$% !&'(<br />

"%4<br />

$!, !&!5(<br />

!"#<br />

$% !&'(<br />

4##<br />

$*% .&!5(<br />

Cut !<br />

Cut '<br />

Cut *<br />

Cut "<br />

Cut %<br />

Cut 5<br />

Then cut out the<br />

rectangles to make the<br />

sides out of<br />

<strong>Frugel</strong>)<strong>Horn</strong> Mk* !v#<br />

Sheet C)' + "x,- !,mm simple cut<br />

layout by Colin Topps<br />

drawn by dld & '.)sept)'#!!<br />

© '#!#/ '#!! Frugal)<strong>Horn</strong>0com<br />

Notes:<br />

!& %mm kerf & trim allowance<br />

'& minimal cuts to break up the sheet 1ie<br />

at the lumber shop2 Dimensions<br />

rounded up to the closest higher mm or<br />

!&,3

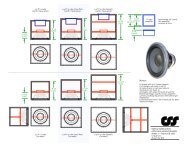

869<br />

[34 3/16]<br />

baffle<br />

baffle<br />

195<br />

[7 11/16]<br />

140<br />

[5 1/2]<br />

830<br />

[32 11/16]<br />

back back<br />

top<br />

top<br />

459<br />

[18 1/16]<br />

bottom<br />

bottom<br />

internal<br />

internal<br />

756<br />

[29 3/4]<br />

140<br />

[5 1/2]<br />

<strong>Frugel</strong>-<strong>Horn</strong> <strong>Mk3</strong> 1v0<br />

Sheet C-4 – 4x8’ 18mm alt cut<br />

layout by David Dlugos<br />

drawn by dld / 25-february-2012<br />

© 2010 – 2012 Frugal-<strong>Horn</strong>.com<br />

Notes:<br />

1/ 5mm kerf & trim allowance<br />

2/ room to increase kerf for CNC<br />

3/ works for 1220x2440mm sheets

459<br />

[18 1/16]<br />

195<br />

[7 11/16]<br />

top<br />

top<br />

bottom<br />

bottom<br />

baffle<br />

140<br />

[5 1/2]<br />

baffle<br />

back<br />

optional parts for a 36mm<br />

tall stabalization base<br />

back<br />

406<br />

[16]<br />

internal<br />

279<br />

[11]<br />

internal<br />

460<br />

[18 1/8]<br />

140<br />

[5 1/2]<br />

756<br />

[29 3/4]<br />

830<br />

[32 11/16]<br />

869<br />

[34 3/16]<br />

<strong>Frugel</strong>-<strong>Horn</strong> <strong>Mk3</strong> 1v0<br />

Sheet C-3 – 4x8’ 18mm cut sheet<br />

layout by David Dlugos<br />

drawn by dld / 25-feb-2012<br />

© 2010, 2011, 2012 Frugal-<strong>Horn</strong>.com<br />

Notes:<br />

1/ 5mm kerf & trim allowance<br />

2/ room to increase kerf for CNC<br />

3/ works for 1220x2440mm sheets<br />

4/ optimized for maximum offcut not<br />

easiest cutting & maintaining grain<br />

matching