Tips on Shop Drawing Reviews

In order to save time on shop drawing preparation and reduce the number of drawing revisions, this shop drawing design review procedure aims to guide our designers on the things to consider when preparing the shop drawings. In this article, I will discuss the common procedure for shop drawing review, but is not limited to, the general drawing review, the material index review, the performance criteria review, the embed layout and detail review, the floor plan review, the general elevation review, the partial elevation review, and the detail review.

General Drawing Review

- The sheet numbers, the submission date, the document references, the material codes, and the number revision are correct.

- The drawing scale, the drawing layout, and the dimensions. Ensure the shop drawings are matched with the submitted structural calculation.

- The cross-referencing is correct.

Material Index Review

The preparation and review of the material index should be done in parallel with the technical specification and IFC drawings issued by the architects and the consultant.

- The glass color, coating, and treatment (temper, heat strength, etc.)

- The aluminum panel thickness, alloy, and finishes.

- The stone thickness, finish, color, and supplier

- The aluminum extrusion alloy, tempering, and finishes.

- The gasket material, hardness, color, and compatibility.

- The adhesive tape material, hardness, color, and supplier.

- The sealant material, function (structural or weather), color, and compatibility.

- The fastener material, size, length, and supplier.

- The insulation thickness, density, and the supplier.

- The grade, thickness, welding, and finishes for mild steel, stainless, and galvanized sheets.

Performance Criteria Review

The review for the performance criteria should be done in parallel with the technical specification, IFC drawings, and wind tunnel test report issued by the architect and the façade consultant. Further, to ensure that the information, data, and reports are read and analyzed accurately, the designer must work along with the façade structural engineer for guidance.

- The designer must ensure that the deflection for panel framing (aluminum mullion, transom, etc.), glass, aluminum panel, etc., are all checked by the façade structural engineer.

- The designer must ensure that the building movement, slab deflection, seismic (if needed), thermal (if needed), and acoustics (if needed) are checked by the façade engineers (structural, thermal, acoustic).

Embed Layout and Detail Review

The design and review of the embed layout should be done in parallel with the technical specification, IFC drawings, and wind tunnel test report issued by the architect and the façade consultant. Further, the façade designer must work with the façade structural engineer or supplier (if any) to ensure the feasibility and workability of the design.

- The type of embed to be used; if steel, consider the steel grade, welding, thickness, sizes, and finishes.

- Ensure the embeds in the layout and details match the submitted structural calculation.

Floor Plan Review

The design and review of the floor plan should be done in parallel with the IFC drawings and wind tunnel test report issued by the architect and the façade consultant.

- The floor plans are matched-projected with the general elevation.

- The dimensions and modulation layout are correct.

- The building reference point is correct, especially when inclined or sloped facades.

- The project North is correct.

- There must have a blow-up detail (if needed).

General Elevation Review

The design and review of general elevation should be done in parallel with the IFC drawings and wind tunnel test report issued by the architect and the façade consultant.

- The building levels are correct, especially when the inclined or sloped facade.

- The building column locations and grid lines are correct.

- The location of BMU is correct (if applicable).

- The call-outs for partial elevations are correct.

- Indicate if the view is developed, projected, or unfolded, especially when the facade is curved or multifaced.

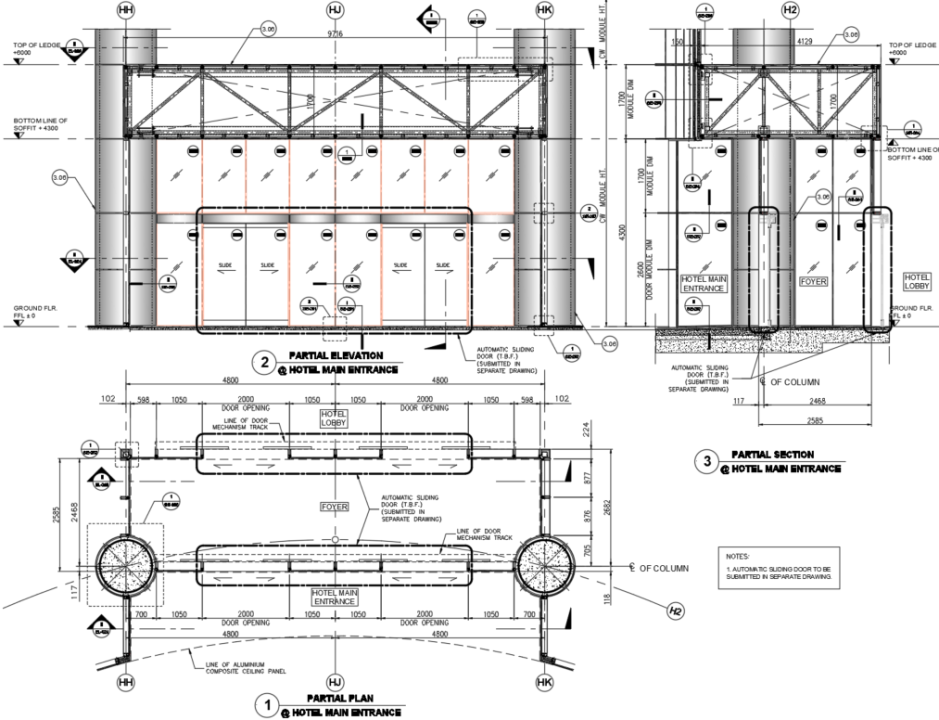

Partial Elevation Review

The design and review of partial elevation should be done in parallel with the general elevation, technical specification, and wind tunnel test report issued by the architect and the façade consultant.

- The drawing has a partial plan, elevation, and section.

- The material designation/code indicated in the material index, such as glass, infill panels, stone, etc.

- The details (typical and non-typical) are correctly called out regarding the horizontal and vertical details.

- The building levels, column location, slab edges, architectural façade line, and grid lines are correct.

- The dimensions (vertical, horizontal, angles) are correct.

- The steel substructure is shown (if any).

- The embed brackets are matched with the embed layout and details.

Detail Review

The design and review of shop drawing details (vertical and horizontal) should be done in parallel with the partial elevation, technical specification, and wind tunnel test report issued by the architect and the façade consultant.

- The vertical and horizontal details shall have the following dimensions: system depth and width, space from the main and sub-structure, joint/sealant gap, and anchorage dimension.

- All material call-outs are correct and listed in the material index; the designer must check the glass, aluminum profile, bent sheets, aluminum panel, stone cladding, sealant materials, gaskets and tapes, air and water seals, fasteners sizes and spacing, fastener types, insulation, and fire safety materials, panel module references, welding, expansion bolts and its minimum embedment, the supplier's code (if applicable), and other material not in the contractor's scope.

- The details (vertical and horizontal) shall match with the submitted engineering report - structural, acoustic (if any), thermal performance (if any), blast (if any), or seismic (if any).

- The tolerance shall consider in the details, such as for the main structure, production, installation, between infill materials, and material expansions.

- Consider the working feasibility at the site, access to installation, maintainability, and design for panel replaceability in the design.

Conclusion

Shop drawing review is a critical process to ensure the design intent, and quality standards, written in the technical specification and analyzed in the report, are met during the production and construction. Let us acknowledge that a shop drawing review is crucial in identifying potential errors, discrepancies, and compliance issues before the actual fabrication and installation of the facade elements.